Before it Cracks

NavAI manufacturing solutions analyze sensor data and historical performance to predict potential equipment failures. Your team can perform proactive maintenance to keep the equipment running smoothly and minimize downtime.

More uptime means more production and profit. But persistent operational challenges can hinder growth and eat into profits. If these common issues sound familiar, NavAI’s manufacturing analytics platform offers a smarter path forward:

Integrate NavAI!NavAI’s manufacturing analytics software delivers a suite of innovative features engineered to empower every aspect of your manufacturing operations, from planning to execution.

Explore Manufacturing IntelligenceNavAI manufacturing solutions analyze sensor data and historical performance to predict potential equipment failures. Your team can perform proactive maintenance to keep the equipment running smoothly and minimize downtime.

NavAI’s manufacturing data analytics delivers precise sales forecasts so you know what to manufacture and stock up on the right raw materials. Align your production perfectly with market demand.

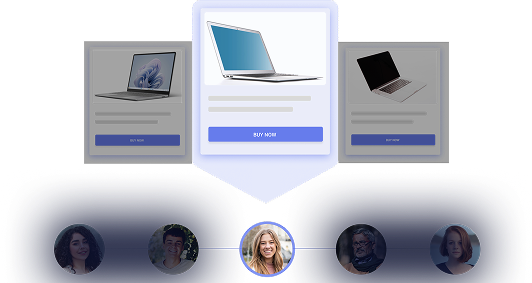

NavAI’s sales data analytics creates comprehensive sales strategies in seconds. It tells you exactly which products to sell to whom and at what price so that your sales team can get right down to work.

NavAI’s manufacturing data analytics software features a conversational interface that allows your plant managers, engineers, and planners to get data-driven insights by asking questions in natural language.

NavAI features a conversational interface. Just ask for what you need in your language, and NavAI will have it served in seconds. Empower all team members to leverage AI in sales and marketing.

NavAI integrates with 320+ data sources such as your ERP (like SAP, NetSuite), MES, SCADA systems, IoT sensors, and quality control databases to provide a single source of truth you can access with just a question.

ML, Data Cleaning, Pipeline, etc NavAI’s conversational interface allows you to extract actionable insights from your data through simple queries. No technical skills are required!

Talk to Your DataYou type your questions into NavAI

NavAI's AI analyzes your query to understand its core meaning

NavAI accesses a vast database of information, including your historical data, real-time feeds, and expert knowledge

Using advanced algorithms and machine learning techniques, NavAI processes the data to identify patterns and trends

NavAI applies sophisticated statistical models and AI techniques to generate actionable insights

NavAI crafts a clear and concise response, often using natural language processing to make it easy to understand

%

Less Stockouts%

Savings in production costs%

Better ProductivityWe treat data security with the utmost seriousness, especially proprietary manufacturing data. NavAI employs industry-standard security measures to keep your data safe. Additionally, it features role-based data access so that every user can access only the data authorized to them.

Not at all. NavAI's core strength is its conversational interface. Our goal is to democratize data. If your team can type a question or use a search engine, they can use NavAI. It's designed to empower your existing team by making complex data analysis accessible through simple language, enabling them to get quick answers and insights.

NavAI is built with flexibility in mind. It can be integrated with a wide range of manufacturing systems, including many legacy platforms. Our unified data approach utilizes various connectors and data ingestion methods to pull data from disparate sources like older MES, SCADA, or even historian databases. You don't need to rip and replace your existing infrastructure to benefit from our analytics.

Yes, NavAI is specifically engineered to handle the high volume, velocity, and variety of data generated in modern manufacturing environments. Our platform utilizes advanced data processing techniques to analyze vast datasets in near real-time, ensuring performance doesn't degrade as your data grows.

Beyond the general areas mentioned, NavAI has been used by manufacturers to identify the root cause of specific, recurring quality defects on a production line. You can optimize scheduling to reduce changeover times and increase throughput for specific product mixes. Along with this, NavAI can help you predict inventory needs for volatile components based on real-time production and fluctuating market signals. You can analyze energy consumption patterns to identify opportunities for cost savings in specific plant areas. We're happy to share case studies relevant to your industry during a demo.

Empower your customer service team with proactive insights and forecasts. Turn every interaction into an opportunity for growth.

Switch to NavAI!